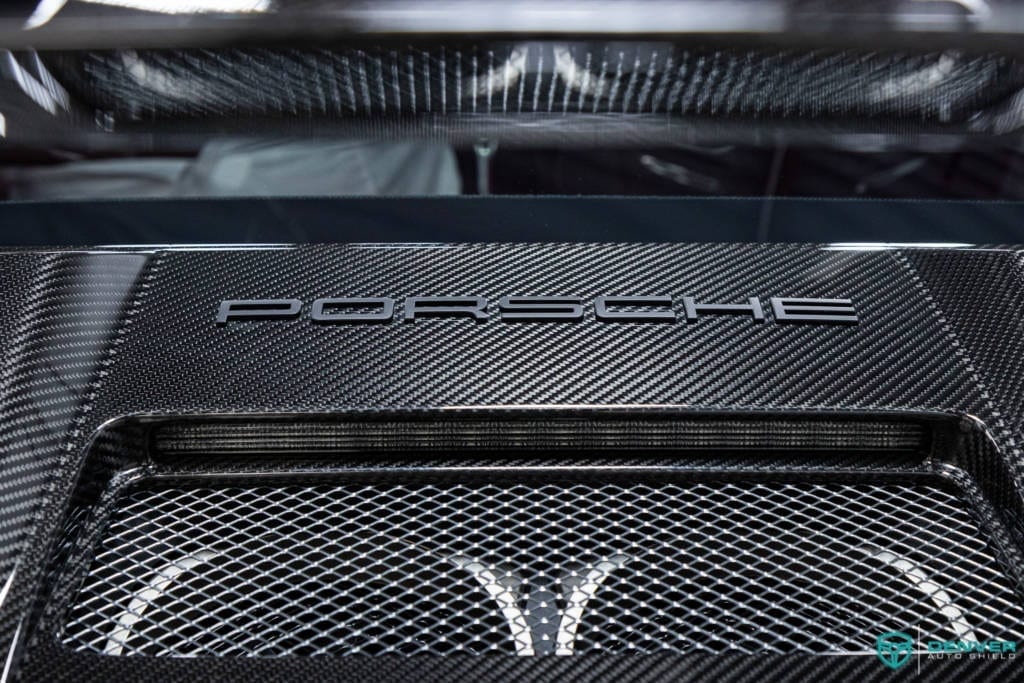

The 911 GT2 RS is one of the most iconic cars on the planet. The 997.2 version is no different. The technology and systems in the car are beyond impressive. So what do you do in order to have as much rip roaring fun in the car as possible without Colorado destroying the finish? Paint Protection Film and Ceramic Coatings of course. This GT RS is in for our Full Body Coverage in XPEL ULTIMATE PLUS Clear Bra and our Level 1 GYEON quartz Ceramic Coating Package.

The first step in our process is always a thorough decontamination of every inch of the car. Even fresh off the delivery truck, the car has seen more life than we often think of before it is “new” to us. It has been on a boat, across an ocean, through multiple rail yards, possibly through multiple dealers, all before you lay hands on it as the new owner.

Before we apply long term protection like clear bra and ceramic coatings, we want perfectly clean paint to interact with. We perform both a chemical and mechanical decontamination to remove below surface and above surface bonded contaminants.

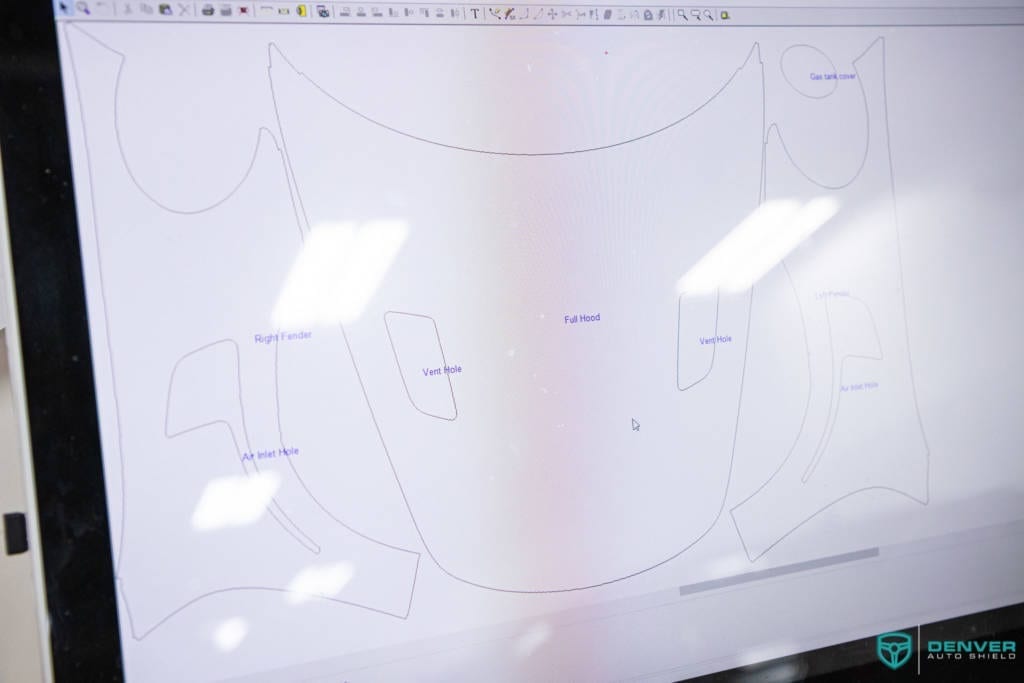

While the car is being cleaned and prepped for install, the clear bra itself is also being prepared. We use the XPEL DAP Design Software to customize the coverage for each car. We can wrap and extend edges, delete cut outs, ad coverage, or anything else we want to do to provide the cleanest finished look with the most coverage possible.

Once the car is clean and the film is prepped, it is time to install the XPEL ULTIMATE PLUS Paint Protection Film!

The final fit and finish of the install is something we take great pride in. If we have done our job correctly, you should not even know the clear bra is in place. This is accomplished by using the XPEL DAP Software and Graphtec plotter to provide us perfectly laid out and customized patterns, and then our Installers taking extreme care to align each piece and wrap all possible edges perfectly.

We do more Porsche 911’s than anything else in our shop. It is always a car we’ve loved working on and a community of people we get along with well. When doing our Full Body Coverage, we install one single and seamless piece of clear bra that starts at the front of the A Pillar, runs all the way back to the point of the tail light, then travels down and across the lower rocker panel to the front of the car to meet the front fender. This is a huge piece of film that we have become very good at installing. This piece plays a huge part in the final finish of the clear bra install and something we are determined to get perfect!

To reach the intricate and lower areas of the car, we use our mid rise under body lifts. These are platform lifts so that we can always access a jack point safely with risers and pucks. They play a huge role in getting the lower fitment just right.

Once the clear bra installation is complete, we allow the car to dry over night before moving on to the next step. We want the slip solution used during the install to dry and permeate through the film. We will walk around the car the next morning checking all wrapped edges and corners to make sure the install is perfect.

Once the clear bra is complete, it is time to move on to the ceramic coating application. The first step in the process is to wipe down the surface with GYEON quartz Q2M Prep. This product will remove any oils or lubricants used in the film install and perfectly prepare for coating application.

For our Level 1 Ceramic Coating Package we use GYEON quartz Q2 PURE. This is a highly concentrated SiO2 ceramic coating formula that bonds well to clear bra, has an intense gloss, will protect the finish from environmental impact, and make regular wash maintenance very fast and easy.

Once the ceramic coating is applied, it is time to sit back and enjoy the finished product! What a gorgeous car.

Are you ready to protect the car you care about? Give us a call today to discuss your project at 720-662-8520.